Strawberry shields forever: bioplastic cuts fruit waste

Jennifer Dudley-Nicholson |

Strawberries come packaged with a hidden environmental toll in Australia: a lot of clear plastic that does not get recycled.

But researchers from the University of Queensland have developed a different way to keep the fruit safe while ensuring biodegradable punnets can return to the farms from which they came.

The discovery, unlocked with assistance from local companies and a Queensland government grant, has been published in a scientific journal, but the researchers say they will need financial backing to manufacture the product at scale.

Among the world’s largest plastic consumers, Australians used 3.9 tonnes of plastic in a year and recovered 14.5 per cent, the most recent government statistics show.

When University of Queensland researchers considered developing biodegradable plastic to address the issue, strawberries were a natural focus due to the amount of plastic used to transport them.

“There’s about 125 grams of strawberries in a punnet and the punnet itself is maybe 12 to 14 grams, which is quite a lot,” Dr Luigi Vandi told AAP.

“When you compare them to oranges, you can buy one kilogram of oranges in a very thin plastic mesh, which is just a few grams.”

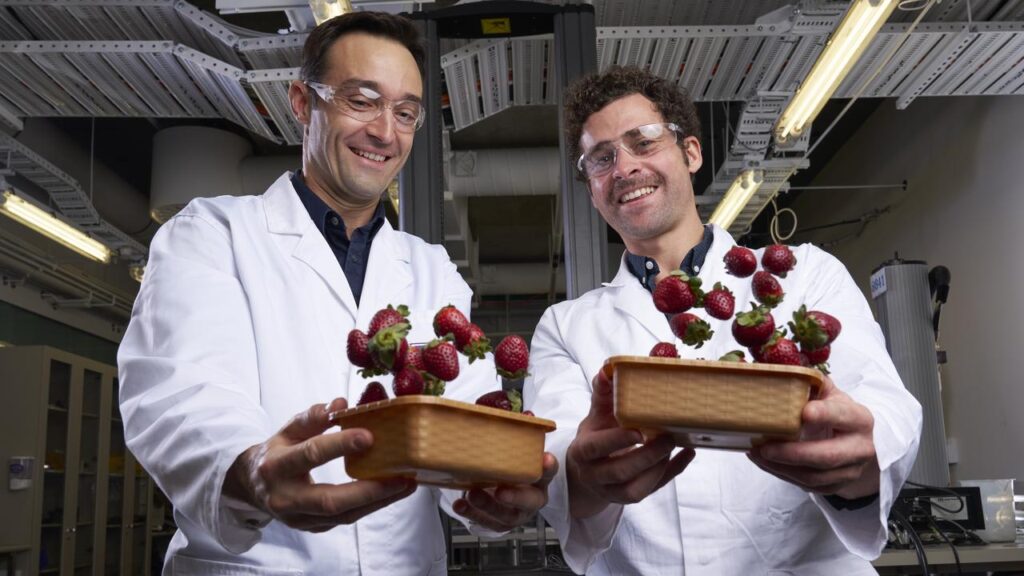

The Centre for Advanced Materials Processing and Manufacturing co-director partnered with PhD candidate Vincent Mathel to produce the bioplastic material in an effort that has taken three years.

Their environmentally friendly packaging uses biodegradable plastic produced by bacteria and blends it with pine sawdust to give it added durability.

Using natural materials that were cheap and could be sourced locally was vital to ensuring it had a positive impact on the environment, Mr Mathel said.

“This is a new material that carries all the sustainability benefit of a bio-sourced product while having the same properties as mass-produced plastic packaging,” he said.

“It was important to us to make biocomposite that maximises Australian resources to have the added environmental benefit that it does not need to be imported from overseas.”

Organisations including injection-moulding firm SDI Plastics and the Queensland Strawberry Growers Association partnered with researchers to test the material, manufacturing more than 200 strawberry punnets and testing them to ensure they could keep fruit intact.

After the successful test, Dr Vandi said the team would investigate recycling options, including turning the material into farm compost, and would seek investors interested in using the environmentally friendly packaging.

“We need end-users who are willing to pay the extra price for it because it is more expensive than the current product,” he said.

“Having said that, it is of much higher value compared to plastic because it doesn’t persist in the environment.”

Details of the bioplastic have been published in the Composites journal.

AAP